Reliability, Condition Monitoring & Asset Integrity Services

Special Oilfield Services Co. LLC (SOS) is one of the leading Condition Monitoring & Reliability companies in the Middle East, with end-to-end solutions and services for all your Reliability improvement, condition monitoring and asset integrity needs. We support your Condition based Maintenance (CbM) program by our value added services viz. Vibration Measurement & Analysis, Dynamic balancing, Precision Laser Alignment, Onsite vibration sensors calibration, Ultrasound based mechanical inspection, valve Inspection, electrical inspection & leak detection surveys, Thermography plant inspection, Steam Trap Inspection, Vibration Analyst Cat I, II, Cat III, Asset Reliability, Laser Alignment Trainings with ISO18436 certification, Insitu & online oil condition monitoring, Intelligent online condition monitoring of Electrical Assets etc.

Insitu Precision Machine Alignment

With our experienced Laser alignment specialists, we deliver high quality & precision alignment services, to the most demanding desired tolerances. We could align machine rotors up to a distance of 20 meters, across the coupling(s).

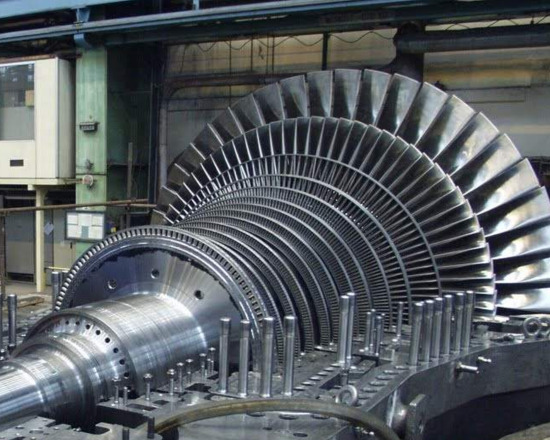

Read MoreInsitu Dynamic Balancing

In-situ balancing of rotating machines at Plant facilities helps running the machines at high efficiency levels thereby improving process throughput and improving product quality. This in turn reduces downtime, labour and material costs.

Read MoreInsitu Sensor Calibration & System Validation

We help validate the end-to-end measurements and check the safety logic functionality of the Turbine Supervisory Instrumentation (TSI) and Machine Protection Systems (MPSs) for Plant’s critical Turbomachinery.

Read MoreInstallation & Commissioning

With an experienced team of Application Engineers, we are well equipped to handle all your installation & commissioning requirements for the Machine Protection & Condition Monitoring Systems supplied.

Read MoreSystem Project Engineering

We can engineer and configure the right Vibration Monitoring System (VMS) architecture for protecting or monitoring your critical rotating assets. We can help you select the right sensors, most effective protection criteria and optimise analysis capabilities for condition monitoring.

Read MoreVibration Acceptance Testing

With an experienced team of Application Engineers, we are well equipped to undertake short-term measurements and measurements over an extended period.

Read MoreVibration Measurement & Analysis

Vibration measurement and analysis (VMA) helps Plant personnel by providing advance warnings of impending equipment failures, thereby giving time to maintenance personnel to plan maintenance actions much in advance & avoid catastrophic equipment failures.

Read More